+7 8552 20-21-17

Заказ обратного звонка

Политика конфиденциальности

Владелец сайта itz-chelny.ru (далее ИТЗ или Администрация) обязуется сохранять Вашу конфиденциальность в сети Интернет. Настоящая Политика Конфиденциальности, рассказывает о том, как собираются, обрабатываются и хранятся Ваши личные данные. Администрация уделяет большое внимание защите личной информации пользователей. Пользуясь сайтом ИТЗ, пользователь тем самым дает согласие на применение правил сбора и использования данных, изложенных в настоящем документе.

Если Вы не согласны с условиями нашей политики конфиденциальности, не используйте сайт ИТЗ!

Собираемая информация

Администрация сайта может собирать следующую информацию о пользователях сайта:

- Фамилия, Имя, Отчество

- Адрес электронной почты

- Номер телефона

Использование информации

Ниже описаны некоторые способы использования личной информации пользователя:

- для внутреннего отчета

- для предоставления информации и услуг, которые запрашивает пользователь

- для ответа на запросы пользователя

- для улучшения качества предоставления услуг

Раскрытие информации

Администрация не продает личные данные пользователя и не передает их третьим лицам без согласия на то пользователя.

Далее, описаны некоторые случаи передачи личной информации пользователя:

- в случаях, если это требуется органам спецслужб или если это требует законодательство

Прочая информация

Дети любых возрастов могут беспрепятственно пользоваться данным сайтом.

STEEL PIPESOF A LARGE DIAMETER

cross-sections Ø530 mm, Ø630 mm and Ø720 mm

with a protective coating of increased reliability

Заявка на приобретение труб

Политика конфиденциальности

Владелец сайта itz-chelny.ru (далее ИТЗ или Администрация) обязуется сохранять Вашу конфиденциальность в сети Интернет. Настоящая Политика Конфиденциальности, рассказывает о том, как собираются, обрабатываются и хранятся Ваши личные данные. Администрация уделяет большое внимание защите личной информации пользователей. Пользуясь сайтом ИТЗ, пользователь тем самым дает согласие на применение правил сбора и использования данных, изложенных в настоящем документе.

Если Вы не согласны с условиями нашей политики конфиденциальности, не используйте сайт ИТЗ!

Собираемая информация

Администрация сайта может собирать следующую информацию о пользователях сайта:

- Фамилия, Имя, Отчество

- Адрес электронной почты

- Номер телефона

Использование информации

Ниже описаны некоторые способы использования личной информации пользователя:

- для внутреннего отчета

- для предоставления информации и услуг, которые запрашивает пользователь

- для ответа на запросы пользователя

- для улучшения качества предоставления услуг

Раскрытие информации

Администрация не продает личные данные пользователя и не передает их третьим лицам без согласия на то пользователя.

Далее, описаны некоторые случаи передачи личной информации пользователя:

- в случаях, если это требуется органам спецслужб или если это требует законодательство

Прочая информация

Дети любых возрастов могут беспрепятственно пользоваться данным сайтом.

ROUND PIPES

DESCRIPTION

PARAMETERS

The standard of GOST 20295-85 extends on steel welded longitudinal and spiral tubes, applied to the construction of the main gas and oil pipelines, oil-products pipelines, technology and field pipelines.

Maximum deviations of the outer diameter of pipes end faces of 2 type with diameter 530 mm and more and type 3 (expended) shall not exceed 12.0 mm for the usual accuracy of production and 11.6 mm for the increased production accuracy.

Steel grade gets out by manufacturer of pipes taking into account requirements for regulations mechanical properties and restrictions according to the maximal substance of elements of steel according to GOST 380. GOST 1050. GOST 19281.

| Pipe size in cross section (mm) |

|

|||||||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | |

| Ø 219 | + | + | + | + | + | |||||||||||

| Ø 273 | + | + | + | + | + | |||||||||||

| Ø 325 | + | + | + | + | + | + | + | + | + | + | + | |||||

| Ø 377 | + | + | + | + | + | + | + | + | + | + | + | |||||

| Ø 426 | + | + | + | + | + | + | + | + | + | + | + | |||||

| Ø 530 | + | + | + | + | + | + | + | + | + | |||||||

ROUND PIPES

PIPES WITH

EXTERNAL INSULATION

PIPES WITH EXTERNAL INSULATION

DESCRIPTION

PARAMETERS

This standard establishes general requirements to protection against corrosion of the outside surface of underground metal constructions (further - constructions): pipelines and reservoirs (including trench type) from carbonaceous and low-alloyed steels, power cables up to 10 kV inclusive; cables of communication and the alarm system in the metal cover, steel nonserviced repeater structures (NR… and regeneration (NRP) points of communication lines, and also the requirement to the objects which are sources of the wandering currents, including to the electrified rail transport, to lines of transfers of the direct current on wire-earth system, industrial enterprises., consuming the direct current in the technology purposes.

The standard does not extend on following constructions: cables of communication with the sheeting of hose type; steel concrete and pig-iron constructions: the communications laid in tunnels, buildings and collectors; piles, tongues, columns, and other similar metal constructions; main pipelines of the compressor, pumping-over and pumping stations, oil depots and head constructions of oil and gas fields; installations of complex preparation of gas and oil; pipelines – heat network with polyurethane foam thermal insulation and the pipe - the cover from tough polyethylene (the design "a pipe in a pipe"), having working system of operating remote control of the condition of insulation of pipelines; the metal constructions located in long-term frozen soil.

| Pipe size in cross section (mm) |

|

|||||||||||||||

| 2 | 2,5 | 3 | 3,5 | 4 | 4,5 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 14 | ||

| Ø 60 | + | + | + | + | + | + | + | |||||||||

| Ø 76 | + | + | + | + | + | + | + | + | ||||||||

| Ø 89 | + | + | + | + | + | + | + | + | ||||||||

| Ø 102 | + | + | + | + | + | + | + | + | ||||||||

| Ø 114 | + | + | + | + | + | + | + | + | ||||||||

| Ø 127 | + | + | + | + | + | + | + | + | ||||||||

| Ø 133 | + | + | + | + | + | + | + | + | ||||||||

| Ø 159 | + | + | + | + | + | + | + | |||||||||

| Ø 219 | + | + | + | + | + | + | ||||||||||

| Ø 273 | + | + | + | + | + | + | ||||||||||

| Ø 325 | + | + | + | + | + | + | ||||||||||

| Ø 377 | + | + | + | + | + | + | + | |||||||||

| Ø 426 | + | + | + | + | + | + | + | + | ||||||||

| Ø 530 | + | + | + | + | + | + | + | |||||||||

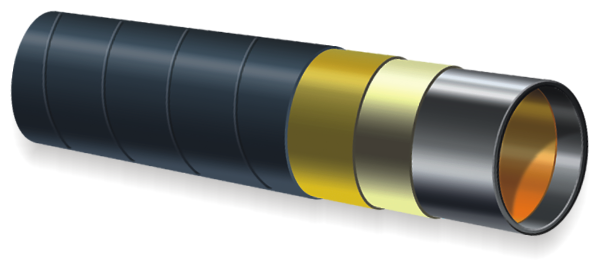

PIPES WITH INTERNAL INSULATION

Plant technology allows to put the following types of

the covering as the internal covering:

Internal "smooth-wall" polymeric covering;

Internal anticorrosive polymeric covering.

Before laying the internal covering, the surface of the steel pipe is subjected to cleaning to the state close to white metal gloss, according to the NACE No. 2, SSPC-SP10, ISO 8501:1, Grade Sa 2 standards. The covering roughness is till 80 microns.

The main benefit of the internal "smooth-wall" polymeric covering it is possible to consider reduction of friction of the transported environment on the pipeline wall.

The internal anticorrosive covering provides protection of the internal surface of the steel pipe against aggressive corrosive attack of the transported environment.

Also, together with the aforesaid, it is possible to allocate the number of positive properties:

- increase in service life, due to increase of corrosion resistance of the pipeline;

- easy and fast input of pipelines in operation;

- the structure of the covering does not influence structure of the working environment in any way, providing its ideal purity;

- turbulence of the flow decreases, thanks to the inside smooth layer;

- reduction of financial provision of the maintenance of the pipeline, thanks to opportunity to reduce diameter of pipes, at the expense of increase in general in pipeline capacity.

PIPES WITH

INTERNAL INSULATION

Отправить сообщение

Политика конфиденциальности

Владелец сайта itz-chelny.ru (далее ИТЗ или Администрация) обязуется сохранять Вашу конфиденциальность в сети Интернет. Настоящая Политика Конфиденциальности, рассказывает о том, как собираются, обрабатываются и хранятся Ваши личные данные. Администрация уделяет большое внимание защите личной информации пользователей. Пользуясь сайтом ИТЗ, пользователь тем самым дает согласие на применение правил сбора и использования данных, изложенных в настоящем документе.

Если Вы не согласны с условиями нашей политики конфиденциальности, не используйте сайт ИТЗ!

Собираемая информация

Администрация сайта может собирать следующую информацию о пользователях сайта:

- Фамилия, Имя, Отчество

- Адрес электронной почты

- Номер телефона

Использование информации

Ниже описаны некоторые способы использования личной информации пользователя:

- для внутреннего отчета

- для предоставления информации и услуг, которые запрашивает пользователь

- для ответа на запросы пользователя

- для улучшения качества предоставления услуг

Раскрытие информации

Администрация не продает личные данные пользователя и не передает их третьим лицам без согласия на то пользователя.

Далее, описаны некоторые случаи передачи личной информации пользователя:

- в случаях, если это требуется органам спецслужб или если это требует законодательство

Прочая информация

Дети любых возрастов могут беспрепятственно пользоваться данным сайтом.

Корзина

Заявка

В корзине пусто

Политика конфиденциальности

Владелец сайта itz-chelny.ru (далее ИТЗ или Администрация) обязуется сохранять Вашу конфиденциальность в сети Интернет. Настоящая Политика Конфиденциальности, рассказывает о том, как собираются, обрабатываются и хранятся Ваши личные данные. Администрация уделяет большое внимание защите личной информации пользователей. Пользуясь сайтом ИТЗ, пользователь тем самым дает согласие на применение правил сбора и использования данных, изложенных в настоящем документе.

Если Вы не согласны с условиями нашей политики конфиденциальности, не используйте сайт ИТЗ!

Собираемая информация

Администрация сайта может собирать следующую информацию о пользователях сайта:

- Фамилия, Имя, Отчество

- Адрес электронной почты

- Номер телефона

Использование информации

Ниже описаны некоторые способы использования личной информации пользователя:

- для внутреннего отчета

- для предоставления информации и услуг, которые запрашивает пользователь

- для ответа на запросы пользователя

- для улучшения качества предоставления услуг

Раскрытие информации

Администрация не продает личные данные пользователя и не передает их третьим лицам без согласия на то пользователя.

Далее, описаны некоторые случаи передачи личной информации пользователя:

- в случаях, если это требуется органам спецслужб или если это требует законодательство

Прочая информация

Дети любых возрастов могут беспрепятственно пользоваться данным сайтом.

Данный сайт использует Cookie

Редактируемый текст